Closed System Flushing & Chemical Dosing Services

Professional flushing and chemical dosing of closed heating and cooling systems to control corrosion, remove contaminants, and protect long-term system performance.

What a Closed System Is

Closed systems are sealed heating and cooling circuits where water is continuously circulated rather than discharged. Examples include low and medium temperature hot water (LTHW / MTHW) systems and chilled water circuits serving HVAC plant.

Over time, oxygen ingress, system modifications, and component wear introduce contaminants into the circulating water. Without intervention, these contaminants accumulate, affecting efficiency and accelerating system degradation.

Closed system maintenance is about preserving system integrity and performance.

Why Closed System Flushing & Dosing Is Required

Untreated closed systems are vulnerable to gradual but significant performance loss.

Common risks include:

Sludge and magnetite build-up within pipework and emitters

Corrosion of steel, copper, and mixed-metal components

Reduced heat transfer efficiency across heat exchangers

Increased energy consumption due to restricted flow

Premature failure of boilers, chillers, pumps, and valves

Flushing and dosing address these risks in a controlled and proportionate way.

When Flushing & Dosing Is Typically Needed

Closed system flushing and dosing is commonly required:

During new system installation or commissioning

Following system extensions or significant modifications

After boiler, chiller, or plant replacement

Where ongoing performance issues are observed

If corrosion, sludge, or debris is evident

As part of planned preventative maintenance programmes

Identifying the right timing helps prevent avoidable damage.

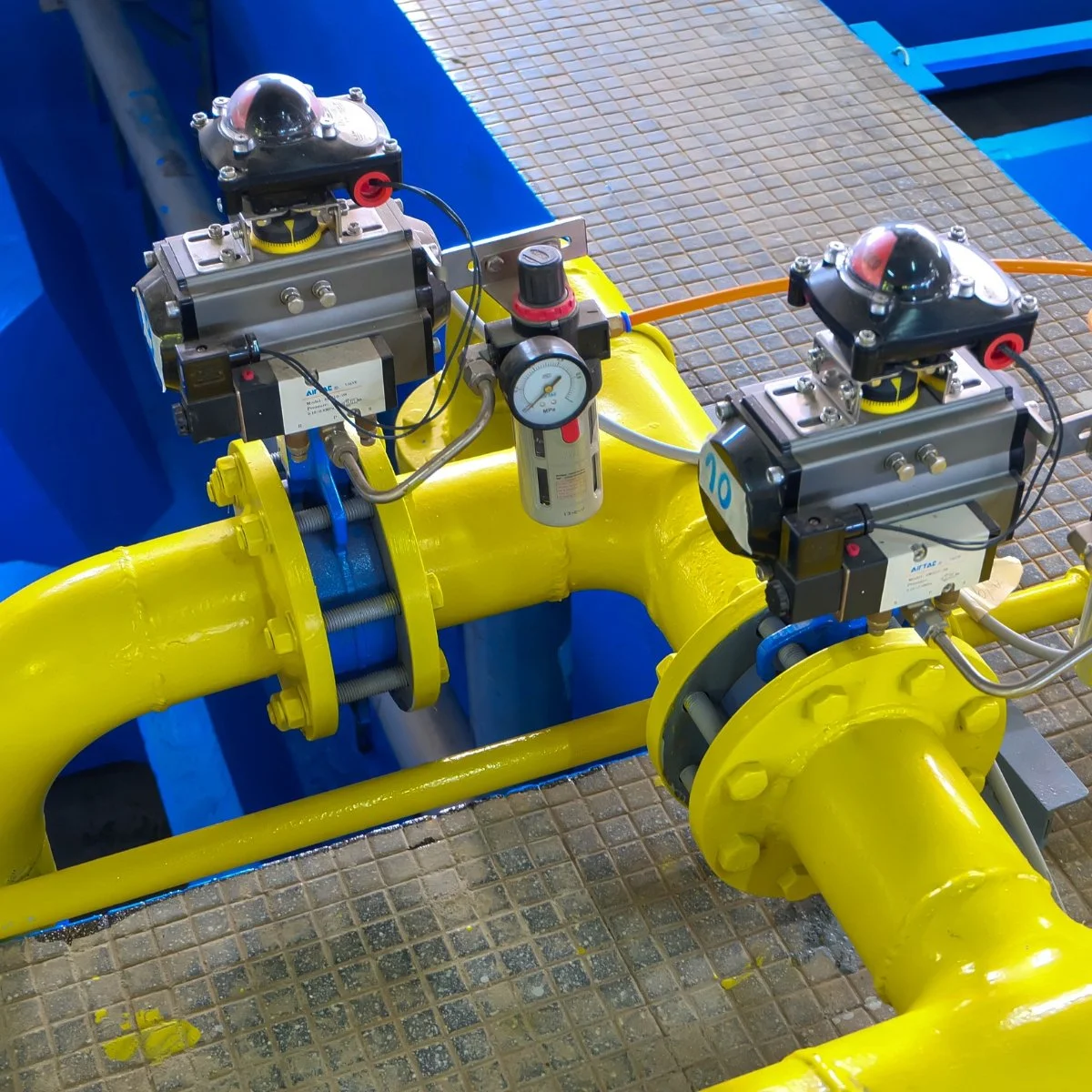

Systems We Service

Flowsafe Compliance services a range of closed systems, including:

LTHW and MTHW heating systems

Chilled water systems

Closed-loop HVAC circuits

Commercial and residential plant rooms

Multi-storey and complex distribution systems

Each system is assessed individually to determine the appropriate approach.

A Methodical, Controlled Approach

System Survey & Condition Assessment

We review system configuration, age, materials, and current condition.

Removal of Debris & Contaminants

Sludge, magnetite, and loose debris are mobilised and removed.

Power or Dynamic Flushing

The appropriate flushing method is selected based on system size and condition.

Isolation & Preparation

Systems are isolated and prepared to allow controlled flushing.

System Refill & Conditioning

The system is refilled with treated water in preparation for dosing.

Performance Verification

Flow, clarity, and basic operational checks are carried out.

Chemical Dosing & Inhibitor Protection

Chemical dosing is a critical part of closed system protection.

Following flushing, appropriate chemicals are introduced to:

Inhibit corrosion of system metals

Control microbiological growth where applicable

Reduce scale formation and fouling

Dosing levels are selected to suit system materials, operating conditions, and manufacturer guidance. Correct dosing protects the investment made in flushing and extends system life.

Standards, Guidance & Best Practice

Our closed system flushing and dosing services are delivered in alignment with:

BSRIA guidance

Manufacturer recommendations

Recognised industry best practice for closed systems

We focus on correct application and suitability rather than unnecessary intervention.

Who This Service Is For

This service is typically used by:

Facilities managers

Building owners

Managing agents

Mechanical and building services contractors

Commercial landlords

Duty holders responsible for plant performance

It supports both operational reliability and asset protection.

How to Arrange Closed System Flushing & Dosing

Initial Enquiry

Contact us to discuss your system and concerns.

1

System Assessment

We assess requirements and confirm the appropriate approach.

2

Scheduling Site Attendance

Works are carried out by a competent engineer.

3

Reporting & Aftercare Guidance

Clear information is provided on works completed and next steps.