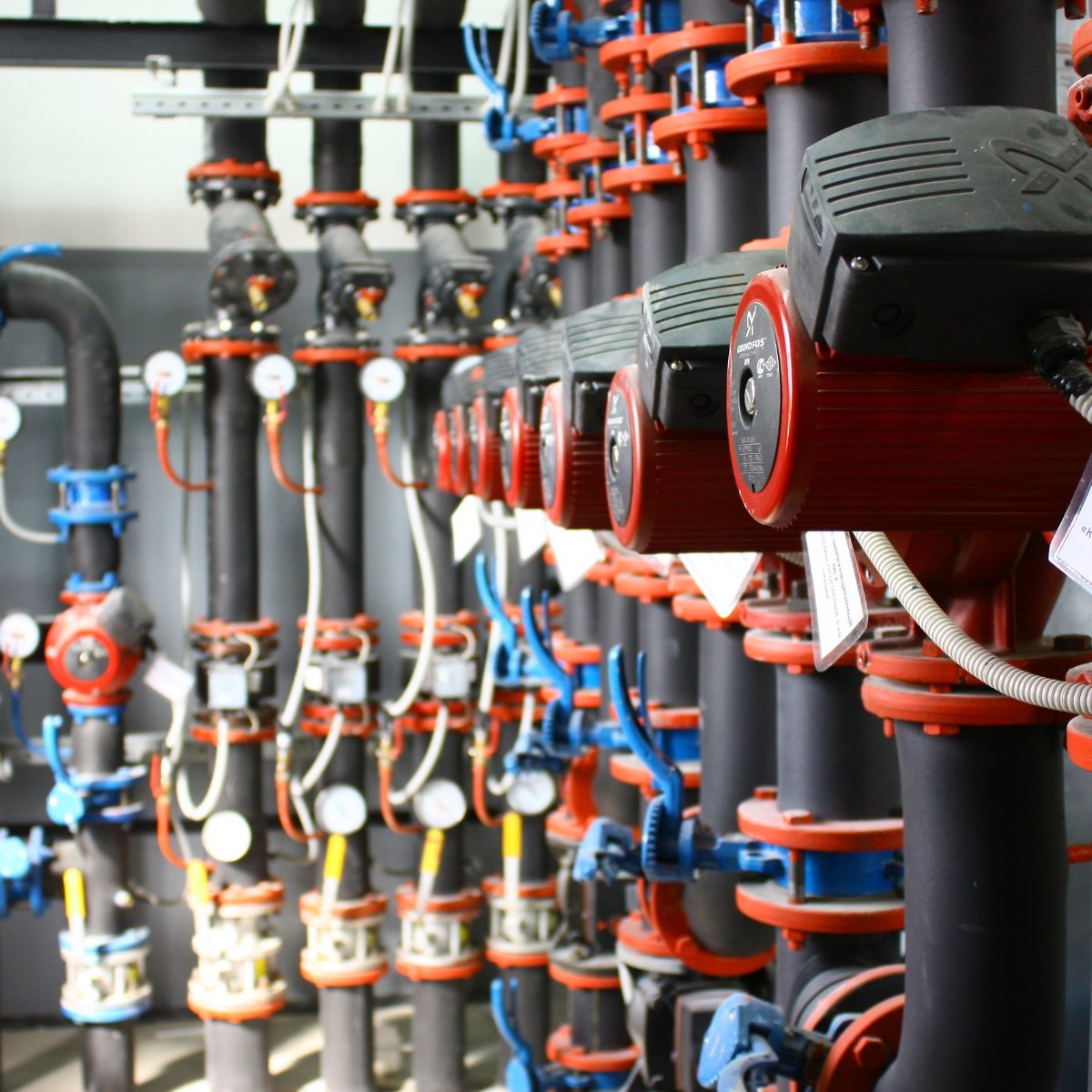

Thermostatic Mixing Valve (TMV) Servicing & Maintenance

Professional inspection, servicing, and testing of Thermostatic Mixing Valves to control scald risk while supporting Legionella temperature management.

What a TMV Is and Why It Matters

A Thermostatic Mixing Valve (TMV) is a safety device designed to blend hot and cold water to deliver water at a controlled outlet temperature.

TMVs are commonly installed in environments where users may be vulnerable to scalding, such as healthcare, education, hospitality, and residential settings.

While TMVs reduce scald risk, they also introduce an additional control point within the water system. If not maintained correctly, they can restrict temperatures, fail mechanically, or become a source of poor performance.

TMV servicing ensures the valve continues to operate as intended, safely, reliably, and in line with guidance.

The Balance Between Scald Risk and Legionella Control

Effective water safety requires balancing two competing risks:

Hot water temperatures must be high enough to control Legionella bacteria

Outlet temperatures must be controlled to prevent scalding

TMVs sit directly at this intersection.

Without regular inspection and servicing:

Valves can drift out of tolerance

Temperatures may fall outside recommended limits

Systems may no longer meet guidance or risk assessment assumptions

TMV servicing supports both scald prevention and Legionella control when applied correctly.

Where TMV Servicing Is Typically Required

TMV servicing is commonly required in:

Healthcare and care environments

Education facilities

Hotels, leisure centres, and gyms

Residential blocks, HMOs, and social housing

Commercial buildings with mixed-use outlets

Any setting where TMVs are relied upon as a control measure should include them within a planned maintenance programme.

Our TMV Services

-

TMV Inspection & Servicing

Routine inspection and servicing to ensure correct operation and temperature control.

-

Temperature Testing & Performance Checks

Verification that hot, cold, and blended temperatures remain within acceptable ranges.

-

TMV Fault Identification & Rectification

Identification of failed, seized, or poorly performing valves, with practical advice on corrective action.

A Controlled, Repeatable Method

Review of Risk Assessment & Outlet Use

We confirm why TMVs are installed and how they are intended to control risk.

Servicing or Adjustment

Valves are serviced or adjusted in line with manufacturer guidance.

Temperature & Performance Testing

Hot, cold, and blended outlet temperatures are measured and recorded.

Visual Inspection & Valve Condition Check

Valves are inspected for signs of wear, scaling, or mechanical failure.

Recording & Reporting

Findings and results are documented clearly for compliance records.

Common TMV Issues Identified During Servicing

TMV servicing often identifies issues such as:

Inaccurate blended outlet temperatures

Restricted hot water flow

Valve seizure due to scale or debris

Inconsistent performance between outlets

TMVs no longer suitable for their location or use

Early identification reduces the risk of failure and unnecessary system disruption.

How to Arrange TMV Servicing

Initial Enquiry

Contact us to discuss your site and TMV requirements.

1

Scope Confirmation

We confirm the number of valves, locations, and testing frequency.

2

Scheduled Site Attendance

A qualified engineer attends site to carry out servicing and testing.

3

Reporting & Record Delivery

Clear records are issued for your compliance files.

4

Alignment With Guidance and Best Practice

TMV servicing is carried out in alignment with relevant UK guidance, including:

HSG 274

ACoP L8

HTM 04-01 (where applicable)

We apply guidance proportionately, focusing on risk control rather than unnecessary intervention.

Who This Service Is For

TMV services are commonly used by:

Facilities and estates managers

Health & safety managers

Property and block managers

Landlords and housing providers

Duty holders responsible for water safety

The service supports both user safety and compliance assurance.